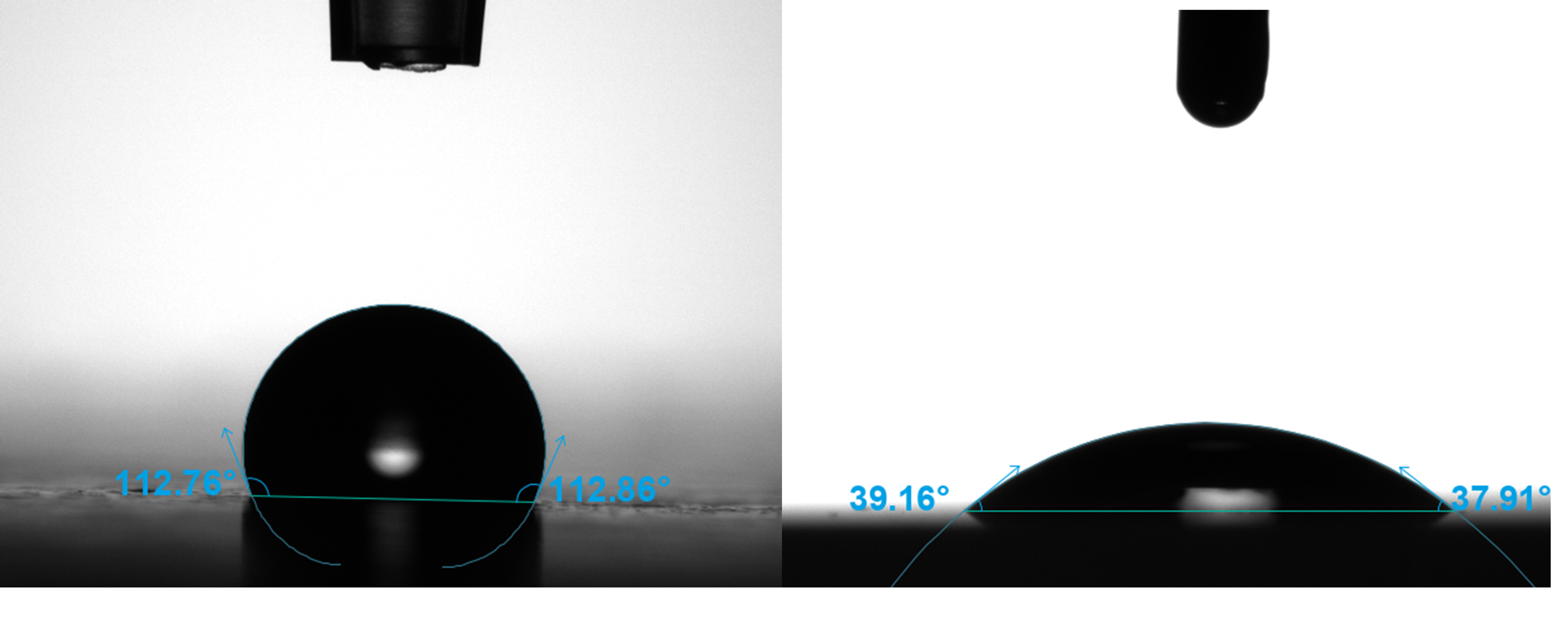

Provides accurate Bresle equivalent measurements of soluble salts on surfaces - over 4 times faster. If the liquid Dyne has a lower surface tension than the parts surface the ink will have a consistent unbroken line.

Free Shipping Over 150.

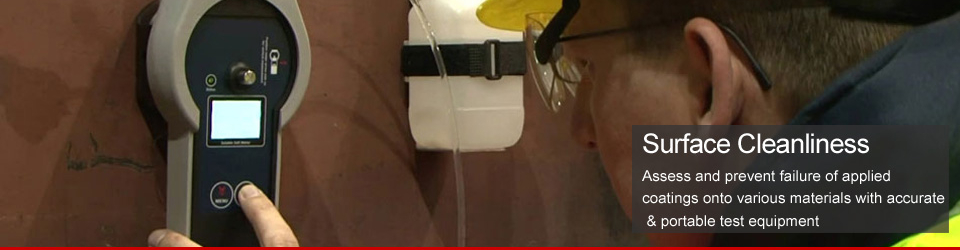

Surface cleanliness testing. We carry a range of Surface Cleanliness Test Kits Probes and products to quickly and accurately determine the surface cleanliness for coating inspection. This is an acceptable surface for coating. Elcometer has a range of test equipment for assessing surface cleanliness prior to applying a coating.

The first step to any cleanliness assessment is to isolate the surface residues from the particular component or area of the component. Elcometer 130 SSP Soluble Salt Profiler. It is used extensively for monitoring chemical and biological contamination as well as particulate contamination in a wide variety of applications 54 55 56 57 58 59 60.

Quickly and accurately measures the level of soluble salts on surfaces. To perform the test the swab is dipped in the target cleanliness Dyne Ink and spread on the part. To ensure the viability of such devices their surface cleanliness must be determined before they can be used in practical applications.

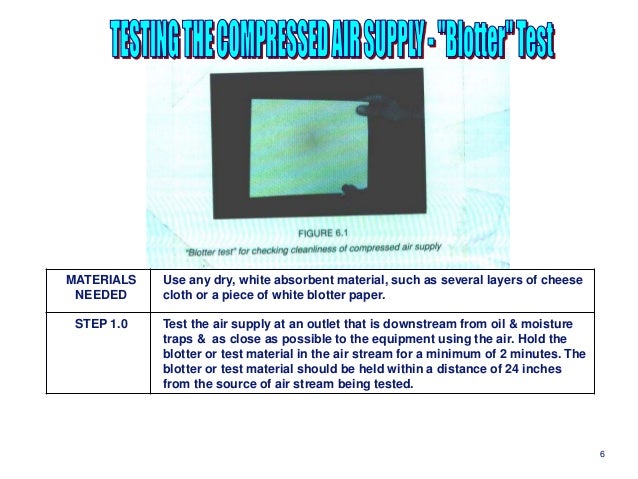

We recommend testing within a range of 15C 59F and 30C 86F and 35 to 70 relative humidity. As weve discussed in a previous article from July 2019 surface cleanliness can be roughly divided into four rust grades ranging from the least soiled to the most. The different standards will specify the techniques allowed to isolate the residues but generally will involve exposure of the particular surface to a particular fluid that has been defined to have specific detergency for the specific residues.

The likelihood of this type product failure depends on depends on 3 major factors1 the environment 2 the circuit performance requirements and 3rd the amount and nature of the surface. Testing for surface contaminants such as soluble salts and ion-specific impurities sulphates chlorides and nitrates is vital to minimise the risk of corrosion ensure strong coating adhesion and achieve the optimum lifetime of a coating. Compared to other legacy cleanliness tests it is relatively simple to perform however the results rely almost entirely on the subjective eye of the person performing the test.

Materials and pieces used in medical devices may be handled multiple times by. One common piece of equipment used to measure surface cleanliness is a surface scanner particle counter a large specialised device that utilises a laser to scan the surface under test for particles. Dyne level testing for cleanliness should always be done at relatively standardized sample ambient and test solution temperatures.

Cleanliness for a carbon steel surface before treatment is defined by the visible level of rust and mill scale. Test for Assessment of Surface Cleanliness Adhesive Tape consists of virtually colorless transparent self-adhesive pressure sensitive tape with adhesion strength of at least 190 Nm and a hand lens capable of magnification x 10. Cleaning today is more that emptying trash cans and running a mop over the floors its a science.

Additionally the surface cleanliness of components is critical for the adhesion of additional coatings and treatments directly correlating to the final quality of the part. The instrument is widely used in Automotive and Aerospace industries and allows users to evaluate cleanliness directly at the. Ideally the range would be 20C to 25C and 40 to 60 RH.

These products must meet stringent cleanliness standards to minimize the risk of post-surgery complications. Cleanliness testing is critical step for any medical device intended for permanent implantation as well as surgical instruments. This is so since the cleanliness desired will depend on the downstream surface treatment process awaiting after the cleaning process.

After a surface has been cleaned samples are taken usually via swab and sent to the hospital lab to gauge which pathogensif anymay still be present. It is used extensively for monitoring chemical and biological contamination as well as particulate contamination in a wide variety of applications 178 179 180 181 182 183. The surface energy of metals is much higher than that of most surface contaminants thus the higher the Dyne level or surface energy mNm also the cleaner the part is.

Cleanliness testing is all about predicting the statistical life of a circuit assembly in a common failure mode often referred to as electrochemical migration. The water break test is a common way for manufacturers to test the surface cleanliness of metals. With increasing standards of cleanliness ever more thorough analyses of parts are required to ensure they meet these high expectations.

Tests for surface cleanliness will evolve to meet changing requirements in how they are used how they can be integrated into an holistic approach considered in relation to developments in legislation reference values audit standards and other needs. Metal Cleanliness Testing. The wipe test is one of the most commonly employed methods worldwide for determining the cleanliness of a surface.

The wipe test is one of the most commonly employed methods worldwide for determining the cleanliness of a surface. There are unfortunately no definitive method for testing for cleanliness of metal surfaces cleaned by the various methods currently. Testing desktop surface cleaned by Multi Level Cleaning Foo.

Our Dyne Test Fluids can also be used to test metal products for surface cleanliness and evaluating the characteristics of their products. The CleanoSpector is an easy-to-use handheld non-destructive cleanliness inspection instrument used for measuring organic contamination such as oil grease and cleaning fluid on metal surfaces. Surface Cleanliness Testing An application frequently requested in our material characterization testing laboratory is a simple assessment of surface cleanliness testing.

Methods For Assessing Surface Cleanliness Sciencedirect

Is It Clean Oil And Hydrophobic Films Water Break Test Ctg Technical Blog

Atp Testing In Covid 19 Safety Rating By Skytrax

Food Hygiene Atp Testing Meter Pce Atp 1 Kit Pce Instruments

Methods For Assessing Surface Cleanliness Sciencedirect

Cleanliness Testing For Printed Circuit Boards Nts

Surface Analysis Lab Surface Chemistry Eag Laboratories

Cleanliness And Quality Control Testing By Contact Angle How Clean Is My Surface Nanoscience Instruments

Adhesion Testing For Protective Coatings Ppt Video Online Download

Allersnap Allergen Prevention Surface Test Instructional Demo Youtube

Uk Supplier Of Surface Measurement And Material Analysis Technology

The Water Break Test As A Surface Measurement Gauge

Water Break Test An Overview Sciencedirect Topics

Surface Dust Test After Sandblasting

Suggested Cleanliness Thresholds And Corre Sponding Rlu For 3 Atp Download Table

Methods For Assessing Surface Cleanliness Sciencedirect

Atp Meter Testing Surface Cleanliness Youtube

Cleanliness Testing Of Components Fraunhofer Ipm

Post a Comment